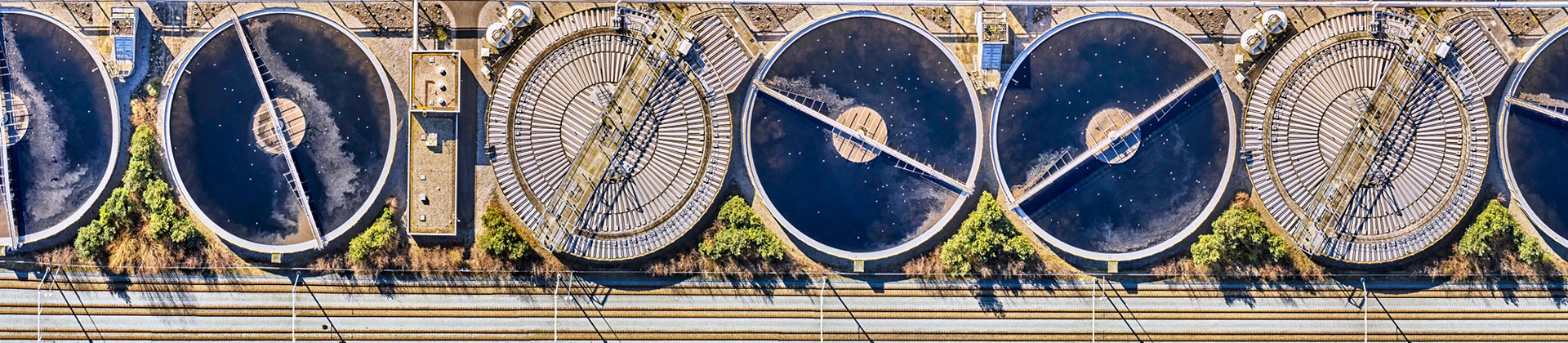

Several factors must be considered when choosing between conventional activated sludge and MBR wastewater treatment

Wastewater treatment is one of the foundations of sanitation and hygiene and can play a major role in preserving aquatic ecosystems and conserving supplies of fresh water. What are some of the differences between two popular wastewater treatment methods, the membrane bioreactor (MBR) and activated sludge processes?

Activated Sludge Treatment

Conventional activated sludge (CAS) is a well-established and proven biological technology that has been used to treat municipal and industrial wastewater for decades. During activated sludge treatment, wastewater is mixed with aerobic bacteria in an aeration tank. The bacteria thrive in the oxygen-rich environment and feed on the organic compounds present in the water, breaking them down in the process. The solids, or activated sludge, are then pumped to a settling tank (clarifier) where they settle, separating them from the treated wastewater. Some activated sludge is returned to the aeration tank to maintain the microbial population, ensuring a continuous supply of microorganisms to the system.

Advantages of Conventional Activated Sludge

Activated sludge treatment is a well-established method of treating wastewater. It offers several advantages, including:

- Proven and established technology: Activated sludge is a tried and tested, robust technology that has been widely used for decades.

- Cost-effectiveness: Activated sludge treatment can be a cost-effective option for larger treatment facilities where space is not limited.

- Adaptability: Activated sludge is adaptable to varying influent conditions, making it suitable for applications including municipal wastewater treatment.

MBR Filtration

This Seven Seas plant provides 50,000 GPD (189 m3/d) of modular membrane bioreactor (MBR) wastewater treatment.

MBR technology is an advanced wastewater treatment process that incorporates elements of the activated sludge process. It’s a biological process that uses microorganisms in an aeration tank to break down and metabolize organic pollutants. However, instead of the water being separated from the sludge in a settling tank, it is passed through filter membranes with fine pores that trap the suspended solids and allow the clean water to pass through. MBR technology is designed to enhance the efficiency of the CAS process by using filtration membranes to achieve efficient solids separation and high effluent quality.

Advantages of MBR

MBR offers several advantages over conventional activated sludge systems, including:

- High-quality effluent: The use of membrane filtration results in low levels of suspended solids and bacteria. The high-quality effluent meets stringent water quality standards and is suitable for reuse in various applications.

- Reduced footprint: MBRs are known for their compact design. The integration of biological treatment and membrane filtration into a single unit removes the need for a separate settling tank, reducing the space required and making it suitable for both new installations and upgrades of existing plants.

- Reduced sludge production: MBRs often produce less sludge than traditional treatment processes. The membrane barrier helps retain and concentrate the sludge, resulting in a more manageable byproduct.

- Decentralized Applications: The modular nature of MBR systems and flexibility in system design and configuration makes them suitable for decentralized wastewater treatment, offering a solution for small communities, remote areas, and industrial applications. They can also be easily scaled up should capacity requirements change in the future.

Major Differences Between MBR and CAS

MBR and activated sludge are both effective wastewater treatment technologies, each with its own set of characteristics and operational principles. The key differences between MBR and activated sludge wastewater treatment are:

Treatment Mechanisms: While both methods use microorganisms to treat wastewater, activated sludge systems include the return of a portion of settled sludge to the aeration tank to maintain a stable microbial population there. This recycling helps ensure continuous and effective treatment. MBR systems, on the other hand, must have a fresh batch of microorganisms added to the aeration tank with each new treatment. Membrane filtration is a key feature of MBR systems, while activated sludge systems rely on clarifying tanks for solid-liquid separation.

Effluent Quality: MBR technology uses ultrafiltration or microfiltration membranes to act as a physical barrier, preventing the passage of solids and allowing only treated water to pass through. This results in higher-quality effluent than CAS systems.

Footprint and Space Requirements: MBR systems have a compact design and smaller footprint than activated sludge systems, which need room to accommodate the settling tanks used in the clarifying process.

Sludge Disposal: Both MBR and activated sludge systems generate biological sludge. In MBRs, the sludge is concentrated within the membrane module, facilitating easier handling. In CAS, sludge handling may involve additional settling and dewatering processes.

Choosing Between CAS and MBR

Conventional activated sludge and MBR each have their own merits, and the choice between the two ultimately depends on the application. MBRs are often chosen where space is limited, where high-quality effluent is required — such as in water reuse projects or in sensitive environmental areas — or where flexibility in system configuration or scalability would be beneficial. CAS systems, on the other hand, are a traditional and proven approach suitable for larger treatment facilities with more available space. They are suitable for a wide range of applications, including municipal wastewater treatment.

To learn more about these and other wastewater treatment technologies, contact Seven Seas Water Group. Our team of water experts will offer you advice and help you choose the best system for your needs.

Image Credit: thelightwriter/123RF

Dr. Amir Ghobadi is a water and wastewater process engineer with over a decade of experience. His expertise includes unit operations, primary, secondary, and tertiary treatment systems, with a focus on membrane filtration and membrane bioreactor (MBR) systems. Dr. Ghobadi holds a Ph.D. in Environmental Engineering and is a certified Professional Engineer. He has developed innovative treatment solutions for industrial and municipal applications, leveraging his deep technical knowledge and commitment to advancing water treatment technologies.